Created a 3D product configurator to streamline the sales-to-manufacturing cycle by 90% and elevate user experience

Kitchen and Cabinetry Configurator

Project Overview

Date

15-05-2024

Customer Profile

Wooden Products Manufacturer

Location

London

Industry

Kitchen and Cabinetry

Categories

Product Configurator

Input

Existing SolidWorks Model, Assembly, Drawing, Quotation, Technical Drawings, Pricing Sheet etc.

Output

DriveWorks Configurator With 3D Preview, Manufacturing Drawing, Quotation, BOM, Email, Cutlist etc.

Software

DriveWorks, SolidWorks

Software we Used

Client

The UK’s leading manufacturer of dovetail drawers & inserts, accessories, trays & inserts, and wooden doors & frames manufactures bespoke sizes and specifications using high-quality timbers. They had the cutting-edge woodworking machinery and highly trained craftsmen, saving your time and money on their own products costs whilst ensuring the quality of the drawer boxes meets the highest standards of premium kitchens, bespoke joinery and furniture being produced for the end clients. They offer a range of options for woods including beech, oak, walnut, maple, MDF and birch plywood drawers.

Client’s Needs

• Develop and set up efficient wooden product configurator for Doors & Frames, Drawers & Inserts, Trays & Inserts, and Accessories.

• Generate the quote from the Drive Works Pro.

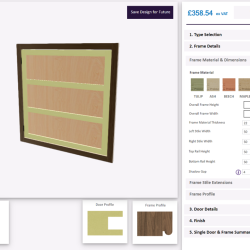

• Create a 3D visualization of the product for the customer.

• Reduction of lead time in generating sales drawing files.

Challenges

-

Easy to update the dimensions in sheet but using Solid Works 2D view in the drawings so difficult to visualize the product.

-

Manul entry in the excel sheet for creating the quote.

-

Order processing dashboard needs to be maintained manually.

-

Difficult to identify the order stages.

-

Manually creating csv file for CNC machine and that also manual entry for all orders.

-

On time delivery of the product.

Solution

-

Initially when clients contact the Design and Automation services Team, our experts examine the process flow of manufacturing & generation procedure they were using and understand their future ideas about what they want.

-

Based on in-depth knowledge of design cycle automation by elimination of repetitive tasks and extensive industry experience, we suggest implementing DriveWorks Pro which diminished the client’s response time.

-

Design and Automation Services develops an efficient product configurator which includes 3D visualization of the product for the customer.

-

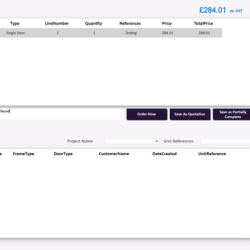

Manual entry of the quote is eliminated by implementation of pricing calculation in the Drive Works and the quote is now automatically generated once the order is placed.

-

3D master models and drawings were developed in Solid Works according to design knowledge of automation.

-

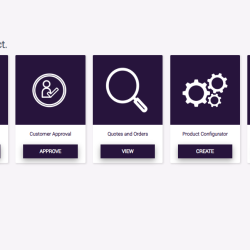

Dashboard for the configurator was created which maintains all the orders on one single platform.

-

CSV files were also created by the Drive Works for the CNC machines eliminating the manual entry for all orders.

-

Later, all design features were captured to automate, and logical rules were used to customize the models and drawings using configurator inputs.

-

Based on configurator inputs, custom models and drawings are generated with accuracy which leads to an increase in productivity.

-

Storing all Data into SQL Database for creating Reporting Dashboards.

-

Benefits of Using Configurator

-

Manual entry for the quote and CSV files for all the orders were eliminated.

-

Implementation of Drive Works configurator provides the 3D visualization of the product.

-

2D Drawings were created from the 3D models so manual changing the dimension of the model were eliminated.

-

Using configurator dashboard can be able to maintain all the orders on one single platform.

-

A major benefit of the configurator was the delivery time of the products within the stipulated time.

-

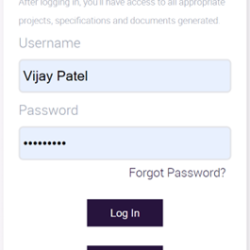

User register in DriveWorks by them self and after approval by sales team they can start generating orders quickly.