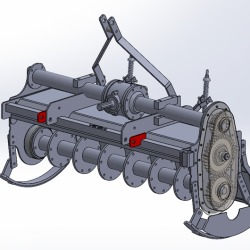

Reverse engineering processes help manufacturers gain valuable insights, improve product performance, and innovate with informed decisions

Agriculture Product design

Project Overview

Date

12-06-2024

Customer Profile

Agriculture Product Manufacturer

Location

Gujarat - India

Industry

Agriculture

Categories

Reverse Engineering, Modeling & Detailing

Input

Dis-assemble Physical Machine for measurement with Engineering tools.

Output

Created paramateria 3D model and Produce manufacturing drawing, DXF, BOM etc.

Software

SolidWorks, AutoCAD

Client

The client sought to implement specific changes to the rotavator design, necessitating a meticulous approach to reverse engineer and redesign the assembly. Leveraging SolidWorks, we meticulously crafted detailed drawings and an assembly of the rotavator, encompassing critical components such as gears, bearings, and shafts. The primary objective was to ensure seamless integration of the proposed changes while upholding the rotavator’s functionality, reliability, and performance standards. Through a combination of innovative engineering solutions, precise design modifications, and rigorous testing, we successfully delivered a tailored solution that met the client’s requirements and surpassed expectations.

Client’s Needs

• Disassemble the product, reverse engineer it and assemble it as it was.

• Make 3d models of all the parts as it assembled with proper assembly structure.

• Make Drafting of each parts & assembly with their drafting standards.

• Make changes as per available market standard parts & electronics.

Challenges

-

Complex mechanism with welded parts, as we have to return product in same condition we have received. so, we can’t break welds.

-

Find matching output & upgraded versions of electronics & other brought out parts.

-

Maintain accurate tolerances of few parts for proper assembly & output of mechanism.

-

Ensuring compatibility and functionality with the requested changes. This involved integrating new components and modifying existing ones while maintaining overall performance and reliability.

Solution

-

Initially when clients contact the Design and Automation Services’s Team, our experts examine the product working & their procedure of manufacturing.

-

Design and Automation Services’ technically sound team get all the technical details & disassembled the tripod with some of images and videos of dismantling.

-

For maintaining accuracy of the measured part, we have used precise equipment like Vernier & micrometer. Even for easy assemble & disassemble the product we also used spanners, screw drivers, circlip plier, rubber hammer etc.

-

We have manually measured each part, make hand sketches of the parts which we can’t take to the out designing system & from the hand sketch we have recreated the 3D models.

-

For few welded parts in mechanism which requires precision & manually we can’t reach to that accuracy, so we have scanned that parts & from the scanned parts we have done reverse engineering.

-

After creating all the 3D models & manufacturing drawings we assembled the product as it was received & tested the working of assembled product to ensure quality.

-

We have reviewed the 3D design & drawings with the client, get feedback for any changes from client’s side.

-

Our experts/senior teams done the final QC and project handed over to the client.