Reverse engineering processes help manufacturers gain valuable insights, improve product performance, and innovate with informed decisions

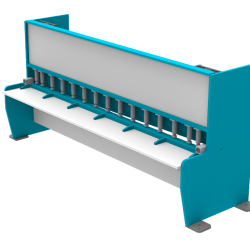

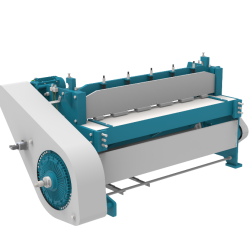

CNC Hydraulic machine

Project Overview

Date

18-01-2024

Customer Profile

Hydraulic Machine Manufacturer

Location

Gujarat - India

Industry

Automotive

Categories

Reverse Engineering, Modeling & Detailing

Input

Dis-assemble Physical Machine for measurement with Engineering tools.

Output

Created paramateria 3D model and Produce manufacturing drawing, DXF, BOM etc.

Software

SolidWorks, AutoCAD

Software we Used

Client

Our client seeks to develop SolidWorks 3D models and drawings for a hydraulic press brake machine. They require comprehensive representations of the machine’s components, including the frame, hydraulic system, bending mechanism, and control panel. Precise measurements and dimensions are essential for compatibility with existing equipment and manufacturing processes. Clear and accessible drawings are necessary for assembly and maintenance. Timely completion is crucial for project progression

Modeling & Drafting Process

To begin the modeling and drafting process for the hydraulic press brake machine, our team will first gather all necessary specifications and dimensions provided by the client. Using SolidWorks software, we will create detailed 3D models of each component of the machine, ensuring accuracy and precision in every aspect. This involves designing the frame, hydraulic system, bending mechanism, and control panel to exact specifications. Once the 3D modeling is complete, we will generate technical drawings that clearly depict each part of the machine from multiple angles. These drawings will include dimensions, annotations, and other relevant information to guide assembly and maintenance processes effectively. Throughout the process, our team will maintain close communication with the client to ensure that their requirements are met at every stage.

Quality Assurance and Validation

Quality assurance and validation are paramount in our approach to serving our client. Before finalizing any deliverables, our team meticulously reviews each aspect of the SolidWorks 3D models and drawings for the hydraulic press brake machine. We conduct thorough quality checks to ensure that all components are accurately modeled and that the dimensions align precisely with the client’s specifications. Additionally, we verify that the technical drawings are clear, comprehensive, and contain all necessary annotations and details for seamless assembly and maintenance. Our commitment to quality extends beyond the initial delivery, as we remain available to address any concerns or provide further assistance as needed. With our rigorous quality assurance processes in place, our client can trust in the accuracy and reliability of the final product.