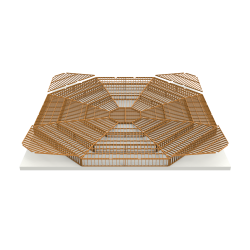

3D modeling & detailing from architectural drawings facilitates streamlined manufacturing processes, ensuring precision and efficiency in production

Wooden Product Design

Project Overview

Date

15-06-2023

Customer Profile

Wooden Product Manufacturer

Location

London

Industry

Wood Industry or Timber Industry

Categories

Modeling & Detailing

Input

Architecture drawing.

Output

Created a parametric 3D model based on the architectural drawing and produced manufacturing drawings, BOMs, etc.

Software

SolidWorks, AutoCAD

Software we Used

Client

The client wanted to turn architectural plans into detailed manufacturing drawings. They wanted these drawings to be precise, adaptable, and done efficiently, with a strong focus on keeping the original design intact. Meeting deadlines was important to them, but they didn’t want to rush the manufacturing process. They also needed the final products to be durable and functional, meeting industry standards.

Modeling & Drafting Process

We utilized SolidWorks software to create an assembly based on the architectural drawings provided. This involved breaking down the components into subassemblies and then assembling them into a main assembly. Following this, we generated detailed drawings for each individual part as well as for the entire assembly, ensuring compliance with manufacturing standards.

Quality Assurance and Validation

We make sure our project’s drawings were accurate, worked well, and could be trusted. To do this, we checked and reviewed everything carefully as we went along, starting from creating the 3D models to making the manufacturing drawings. We looked closely at the sizes, details, and how everything fit together, fixing any mistakes quickly.

We kept talking with everyone involved and listened to any ideas or concerns they had. This way, we all worked together to make sure everything turned out the way the client wanted and met the standards of the industry. In short, we made sure everything was right every step of the way, so the client could trust that the drawings we made were top-notch.

Steps of the Project :

-

Client Requirement Analysis

The project commenced with a comprehensive analysis of the client's requirements. The client sought to translate architectural drawings into manufacturing drawings for the production of custom furniture pieces.

-

Architectural Drawing Assessment

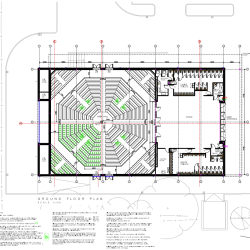

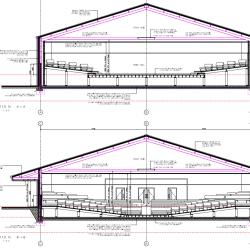

Detailed examination of the architectural drawings provided by the client was conducted to understand design specifications, dimensions, and material requirements.

-

3D Modeling on SolidWorks

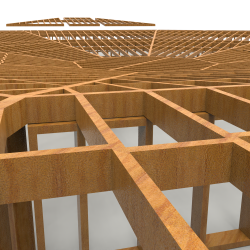

Utilizing SolidWorks software, the architectural drawings were transformed into accurate 3D models. This step involved creating virtual representations of the furniture pieces based on the architectural designs.

-

Subassembly and Main Assembly Creation

The 3D models were further refined by breaking down the components into subassemblies and assembling them into a main assembly. This process ensured a clear understanding of the structural composition of the furniture pieces.

-

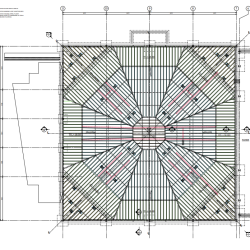

Detailed Manufacturing Drawings

Detailed manufacturing drawings were generated based on the 3D models created in SolidWorks. These drawings included precise measurements, material specifications, assembly instructions, and other relevant details essential for production.

-

Quality Assurance and Validation

Robust quality assurance measures were implemented throughout the project to ensure accuracy and reliability. Thorough reviews and checks were conducted at each stage of the process, from creating 3D models to generating manufacturing drawings. Additionally, validation processes were employed to confirm the feasibility and suitability of the design for manufacturing.

-

Finalization and Delivery

Upon completion of the manufacturing drawings, the finalized designs were delivered to the client for review and approval. Any final adjustments or revisions were made based on client feedback before proceeding to the production phase.